Stephen J. Thomas, Subject Matter Expert

There is often a conflict between Operations and Maintenance regarding how corrective maintenance work is executed. What is commonly heard from Operations is, “we prepare the equipment based on the work schedule but often Maintenance doesn’t show up.” From Maintenance’s perspective what is often heard is, “we follow our work schedule and when we show up to perform corrective maintenance Operations has not prepared the equipment.” On the surface these two comments appear to be at odds with one another since the ultimate goal is to maintain the equipment in such a manner as to avoid any unplanned failures. So what happens to cause this problem? If Operations follows the schedule and prepares the equipment for Maintenance the next day, and on a continual basis they fail to show up, over time the operators are not going to take the time to prepare the equipment as scheduled. When the process is followed and Maintenance does show up the equipment will not be ready for work leading to Maintenance’s is level of stated frustration. This type of poor work execution should not happen. In order to maintain a high level of effectiveness and efficiency we need to examine why it does and what can be done to avoid this problem.

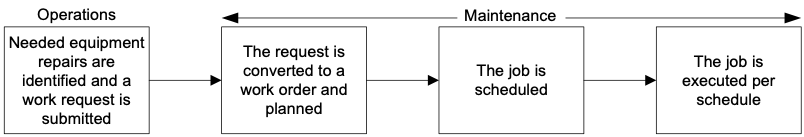

A normal maintenance corrective action planning and scheduling work process functions as described in figure 1. In this process, Operations identifies a maintenance related problem, executes a work request that is submitted to the planner who then turns it into a work order with the appropriate planning and schedules it for execution. With good communications between Operations and Maintenance one would think that following this process, 1) Operations would have the equipment prepared and 2) Maintenance would show up per the work schedule.

The one major element that causes a break in the work schedule is what is typically referred to as the emergency work order or “E” job for short. An emergency work order is created by Operations when there is a significant maintenance related problem and the maintenance crews need to be diverted from their current schedule to immediately fix the problem. This process is highly effective to avoid serious problems from escalating and possibly causing an unplanned unit shutdown. However the use of the emergency work order is also a mechanism for individuals to subvert the work order process. This subversion in an ideal world should not happen, but it does. The reason is often due to a large maintenance backlog causing certain operating units to have to wait for repairs to their equipment over an extended period of time. Often the leadership of these units considers this an unacceptable delay. To address this problem, they often will submit an emergency work order when an emergency really does not exist. Their purpose is to escalate their repair work above the other jobs on the work schedule and get the immediate attention that they believe is their just due. The problem with this approach is obvious, and leads to the conflict between Operations preparing equipment for work and Maintenance showing up to perform repairs.

One would think that Maintenance could recognize this subversive approach to getting an individual’s work orders moved up in the queue, but that does not often happen. The reason for this is that Maintenance’s philosophy is that their customer is Operations and they need to address the identified operating emergencies as they occur. In large plants where there are many operating superintendents, all who are peers of one another, this philosophy causes serious issues if non-emergency work is submitted as an emergency. The end result of subversive emergency work requests is that the planning and scheduling process will break down causing interdepartmental conflict and loss of effectiveness and efficiency of the overall effort.

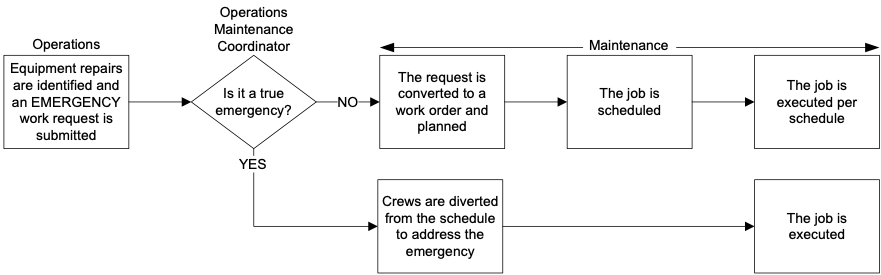

There is a solution to this problem! What is needed is a new job role called the Operations / Maintenance Coordinator. This position in the work process sits between the operations organization creating work requests and the maintenance planning and scheduling organization that processes these requests into work orders and ultimately work execution.

The primary role of this position is to assure that the maintenance work schedule is executed as created and subversive emergency work orders are recognized for what they are and not allowed to cause diversion of the work crews to jobs not on the schedule. In other words the Operations / Maintenance Coordinator is the traffic cop analyzing the incoming emergency jobs and determining whether or not they are of sufficient criticality that they need immediate attention. This process is described in Figure 2.

This position is not an easy position to fill. What is required is someone within the operations organization who possesses a high degree of credibility with his or her operating peers. They also need to be independent in their thinking and have a significant understanding of the entire operating process. They need to be able to decide whether a job is truly an emergency or just an individual in the operations organization trying to escalate their work in front of others in the queue. One way for you to know that you have the right person in the job is that they are disliked by both the Operations and Maintenance organizations because many of the decisions they make are not viewed favorably by either organization. Nevertheless their primary job is to assure that true emergencies are addressed as such and emergencies to escalate an individual’s work requests to a higher level are rejected and handled accordingly.

To accomplish this role, the Operations / Maintenance Coordinator needs to have a high degree of visibility in the work process. The way this can be accomplished is to have this individual run the Operations / Maintenance morning meeting. This meeting usually takes place prior to the initiation of the day shift and includes representatives from both organizations as well as others that may be impacted. It is at this meeting where any true emergencies are identified and the coordinator working with Maintenance can divert the work crews to address the issues. The coordinator also needs to meet later in the afternoon with the maintenance supervision to determine if there are any adjustments needed for the next day’s schedule due to work that was planned for the current shift but was not able to be completed.

The coordinator also has a significant input into jobs that may need to work overtime. In plants that do not have this position, determining jobs that may require overtime is left to the operations leader of that particular operating area to make that determination. These decisions are not always made with cost effectiveness in mind. An example of this type of decision could be a failed primary pump within a processing unit where a viable backup exists.

Often Operations will request overtime to return the primary pump to service even though the backup is fully reliable and entirely capable of handling the processing demands. In this example, the coordinator would rule out overtime and schedule the repair for the future.

If your facility is experiencing problems with interrupted work schedules due to subversive emergency work requests being submitted then I would suggest that you consider creating the position of Operations / Maintenance Coordinator. With this position as part of your maintenance work process you will find that the effectiveness and efficiency of the work crews will increase and problems with communication and coordination of the work will be diminished. Choose wisely because this is probably one of the most critical positions that is part of the maintenance planning, scheduling and work execution process.