PK Technology | June 4, 2018

Executive Summary

PK Technology provides a mobile integrity management tool for all assets through proven intelligent technology. This approach improves the efficiencies related to inspection, consistency in reporting and evaluation of data collected from inspector to inspector. Consistency of inspection results aid in the decision-making process related to prioritizing and planning of repairs or replacement of the piping and fixed equipment. Technology also provides a more effective and consistent means for determining the effectiveness of each inspection relating to the predicted damage mechanisms and updating the RBI analysis.

PK Technology’s approach to this type of project encompasses the knowledge and experience of our RBI Experts, mobile inspection technology and our proprietary RBI module that follows API 580/581 as guidance. By using PK Technology’s RBI Program, the client will receive the best minds in the industry, world-class mobile technology, superior quality and increased efficiency.

Some key benefits of Risk-Based Inspections are:

• A more cost-effective alternative to traditional inspection, usually by means of nondestructive testing.

• More reliable equipment and plant operation.

• Identification of the operational risks associated with equipment via material degradation.

• Adherence to codes of compliance resulting in increased safety.

• Reduction in plant downtime.

In addition to the benefits noted above, each person responsible for this initiative will be able to view the progress of the project or results of the program based on KPI dashboards that fit specific areas of interest. Dashboards are updated in real-time and are constantly accessible to the client. The dashboards display a snapshot of the project’s KPIs and critical metrics – this result simply cannot be replicated without the compilation of all data captured within intelliSPEC™.

Methodology & Implementation

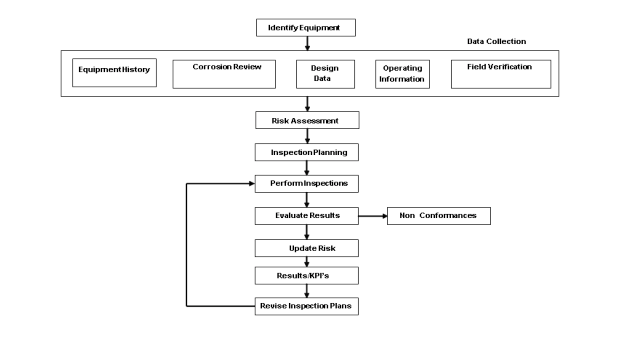

To properly implement PK Technology’s RBI Program, a specific data set must be collected to calculate and determine the Consequence of Failure (COF) and Likelihood of Failure (LOF) for an asset. As a part of this project, intelliSPEC’s™ RBI module may utilize specific data collection forms to capture the required data for risk to determine the LOF and COF utilized in establishing the basis for the inspection plan. PK Technology will perform the following activities as part of the implementation process:

• Develop piping systems and circuits

• Develop equipment and piping circuit tracking logs.

• Data collection and review of fixed equipment and piping circuits.

o Design data

o Operating data

o Inspection history review

• Corrosion/damage mechanism review

• Sketching and external visual inspection of piping circuits

• External visual inspection of fixed equipment

• Calculate risk ranking for each asset included in the project scope

• Create an Inspection Plan for each asset included in the project scope

• Perform external required ultrasonic thickness measurements for piping and fixed equipment as required per the inspection plan:

o The client will be responsible for providing access to locations that require the use of a manlift, or other means, removing insulation for NDE, follow-up inspection or providing profile radiography if required.

o PK Technology will utilize existing NDE locations for fixed equipment and recommend additional locations based on the risk ranking and damage mechanisms for each asset.

Defining Piping Circuits

A qualified inspector is used to define piping circuits. Piping circuits are defined as sections of continuous pipelines exposed to an environment of similar internal corrosivity, similar operating conditions and similar materials of construction. Piping circuits are defined and identified on P&IDs provided by the customer to organize the piping into manageable segments as an intermediate step in the development of an inspection program.

The piping circuit ID will be used as a reference for all MI related activities associated with the piping

included in the piping circuit (i.e., the Circuit ID becomes the equipment ID).

Developing Tracking Lists

Tracking lists are developed to:

• Identify equipment items included in the project scope

• Provide a quick reference identifying tasks to be performed, tasks completed and incomplete tasks for planning/organizing on-site work and for progress reporting

Tracking Lists include all equipment items within the scope of work and are separated by unit and equipment type. Tracking lists may vary depending upon project scope and it may require modification to accommodate varying projects and/or tasks.

Piping Circuit Tracking Lists use the Piping System/Circuit Identification Log to generate the tracking list for piping circuits and used to identify how many circuits are in each piping system.

Once developed, the tracking lists should be accessible to all project personnel. Project personnel indicate the completion of a task by putting the completion date and their initials in the appropriate column on the tracking list.

Data Collection

Data is collected for equipment items for three reasons:

1. To predict damage mechanisms and degradation rates.

2. Develop inspection plans based on RBI inspection strategies provided by the client and/or API 510/570/653 guidelines for time based fixed equipment and piping.

3. To create an electronic reference for equipment information that would otherwise only be accessible in paper equipment files.

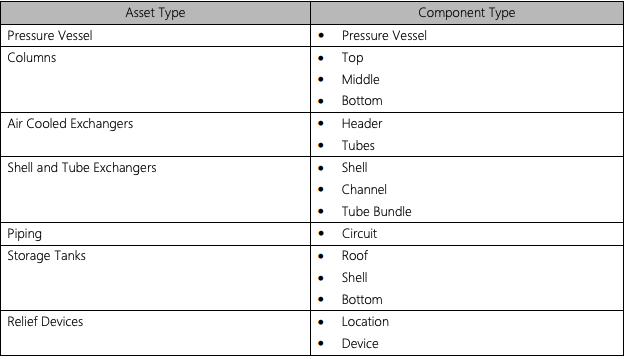

Data is collected for both assets and components. Assets correlate to an equipment item or piping circuit on the equipment lists (for example, a heat exchanger, a piping circuit, a storage tank). A component is part of an asset (for example, tubes, channel, and shell are all components of a heat exchanger).

The types of assets and components typically available in intelliSPEC™ are listed below and all include the ability to add jackets

Corrosion Review

The corrosion/damage mechanism review process will provide an understanding of a unit’s operating process, design conditions, materials of construction, maintenance and inspection history to determine potential damage mechanisms, corrosion types and corrosion rates to be used in Calculating Risk and developing the Inspection Plan. A Corrosion Technologist or Engineer will utilize information collected by the on-site project team and facilitate the meeting to review operating conditions, process conditions, maintenance activities and future expectations to aid in the identification of damage mechanisms and expected deterioration rates. The four basic steps of a corrosion/damage mechanism review will be to review historical or similar corrosion rates, preparing documents for the on-site review, performing the on-site review and documenting the corrosion/damage mechanism review on the PFD’s/CMD’s.

Meetings

Several meetings will be required between PK Technology and the Client during the project to ensure the quality and accuracy of the data used for the risk analysis and inspection plans.

• A kick-off meeting (2-4 hours) to start the project will cover administrative and technical details including project reporting, scope, deliverable clarification, etc.

• A corrosion review meeting (typically 4 hours) will take place involving an Operator, Process Engineer, Inspector, Reliability Engineer and the client Project Manager. PK Technology representatives will include the Project Manager and Corrosion Engineer.

• Discussion and review of inspection strategies may be scheduled.

• A risk review meeting will be scheduled for each unit to validate damage mechanisms and the driving risk of each component. These meetings are typically 4 hours and similar client representatives as the corrosion review should attend.

• A project close-out meeting will be held to review the risk ranking, inspection plans and approve project deliverables between PK Technology and the client.

Project Execution Plan

PK Technology’s approach is based on our managed inspection process using unique mobile data collection technology and management tools. All visual inspections are performed on an iPad utilizing the intelliSPEC™ application where our inspectors fill out the form, annotate the drawings, take pictures and connect to external Bluetooth devices all while collecting various data to a single inspection point. In this unique approach, we work with our clients to develop dynamic dashboards to track inspection findings, data analytics and work progress. These dashboards add to the transparency and organization of our projects.